Rare Earths: The Hidden Engine Behind the Green Energy and Tech Revolution

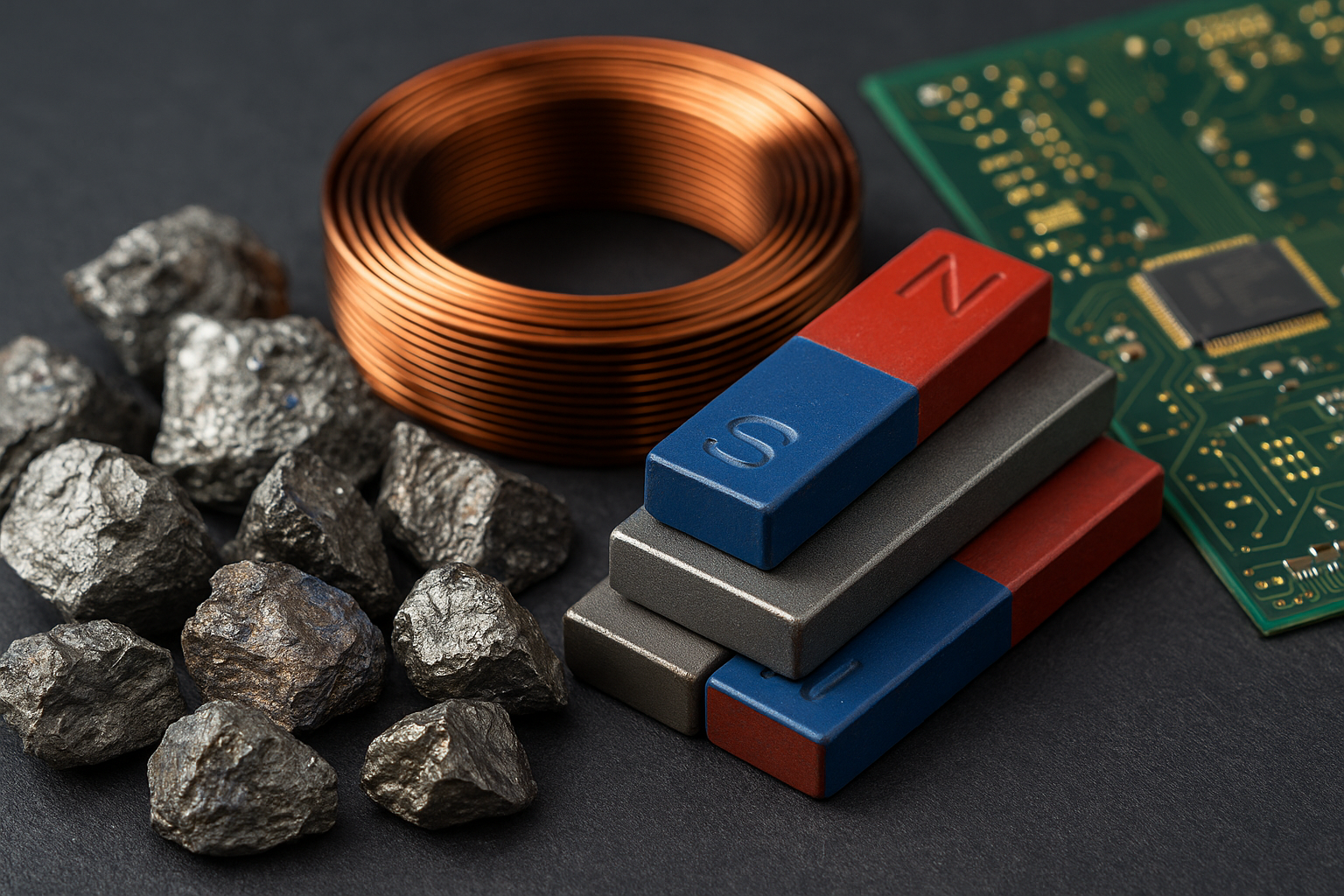

Rare earth elements, or REEs, take up only a tiny space in the periodic table, yet they have become essential to the technologies that power modern life. For years, these minerals were rarely discussed outside specialist circles, despite enabling everything from powerful magnets to precision electronics. That reality has changed. As the world accelerates toward electrification, decarbonisation and AI-driven computing, REEs have become one of the most strategically significant and geopolitically sensitive commodity groups in global markets.

From electric vehicle (EV) motor magnets and wind-turbine alloys to materials that power advanced AI chips, REEs are central to the shift toward cleaner energy and smarter technology. Yet the simplicity of this story ends quickly. Supply remains heavily concentrated, new processing infrastructure is slow and expensive to build, and geopolitical tensions continue to shape access to these critical minerals. For investors, this creates a long-term structural theme that spans mining, refining, advanced manufacturing and national-security considerations.

Why Rare Earths Matter Now

The global push toward clean energy and digital technology has elevated the importance of REEs across supply chains. Although there are 17 rare earth elements, only a select group plays an outsized economic role, particularly neodymium, praseodymium, dysprosium and terbium. These elements are used to make high-strength permanent magnets that are essential for EV motors and wind turbines, two pillars of global decarbonisation efforts.

Beyond clean energy, REEs are deeply embedded in everyday technology. They are used in smartphones, medical imaging devices, lasers, defence systems and the components that power artificial intelligence and hyperscale data centres. REEs improve efficiency, durability and heat resistance, characteristics that are increasingly valuable as computing becomes more advanced and energy systems become more electrified.

As a result, REEs have shifted from niche industrial inputs to strategic materials shaping economic and technological competitiveness. This has led governments and manufacturers to compete for reliable access not only to raw minerals but also to the critical midstream steps of processing, separation and magnet manufacturing.

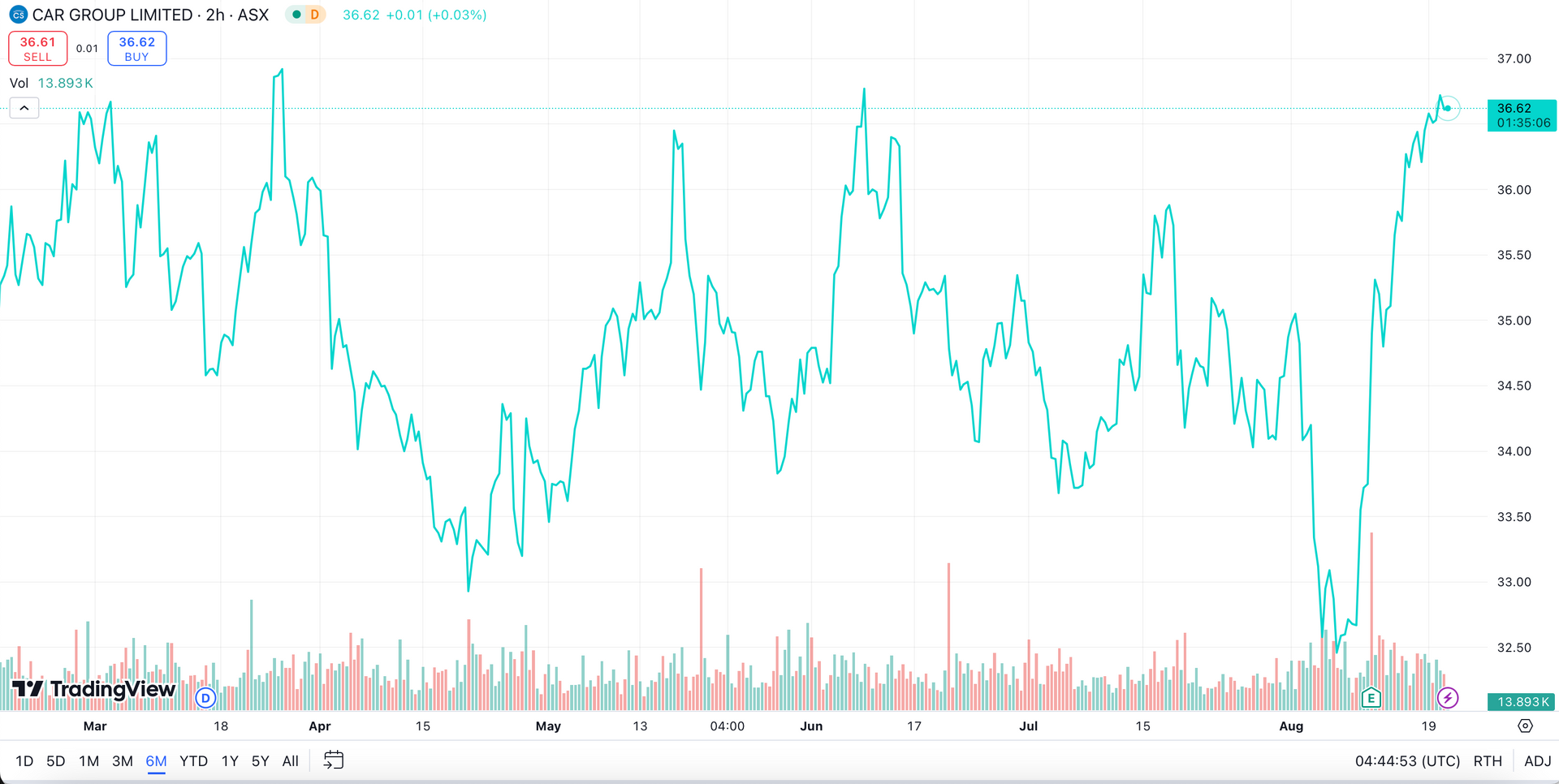

Demand Drivers: Green Energy, EVs and AI Hardware

The global economy is undergoing a structural shift toward electrification, renewable energy and data-intensive computing, placing rare earths at the core of several growth industries. EVs are one of the strongest demand drivers. Most EV motors use neodymium-iron-boron magnets that contain neodymium, praseodymium and small amounts of dysprosium. Each EV contains roughly one to two kilograms of these materials. With EV sales expected to exceed 30 million units annually by 2030, demand for magnet metals is set to rise. Industry forecasts project the broader REE market to grow at a rate of 6.5% to 8.5% a year from 2025 to 2030.

Wind turbines, particularly offshore systems, are also major consumers of REEs. Direct-drive turbines rely on significant volumes of Nd, Pr and Dy to achieve high efficiency and low maintenance. Global wind capacity is forecast to nearly triple by 2035. Industry estimates show the wind sector expanding from USD 115.3 billion today to USD 361.2 billion by 2035, reflecting annual growth of nearly 11%. Offshore wind, which requires more robust and heat-resistant magnets, will drive a substantial share of future demand.

Electronics and AI hardware also contribute to growing consumption. Machine-learning accelerators and optical components use REE-derived materials, while data centres rely on them for cooling, robotics and power systems. Consumer electronics remain a steady demand base, with REEs used in displays, audio systems and imaging equipment. Altogether, the Rare Earth Mineral Concentrates market was valued at USD 11.6 to 17.8 billion in 2024 and is expected to grow at 6.5% to 8.5% annually through 2030. This creates a clear pattern: REE demand is accelerating across multiple industries at once, intensifying long-term pressure on already limited supply.

Supply‑Side Constraints and Geopolitical Risks

Strong demand confronts a supply chain that is tightly concentrated and difficult to diversify. China accounted for roughly 69% of global rare-earth mine output in 2024 and controls an estimated 88% to 92% of all refining and separation capacity. It also produces close to 98% of the world’s NdFeB magnets. This level of control gives China considerable influence over industries that rely on REEs, including EV manufacturing, renewable energy, electronics and defence.

The strategic exposure became more evident in 2025 when China introduced stricter export licensing for several heavy REEs such as dysprosium and terbium, along with certain refined products and magnet inputs. These measures raised concerns across global supply chains. Although China later issued a temporary pause by granting a small batch of streamlined export licences, supply uncertainty remains. Even minor export policy changes can tighten availability, increase price volatility and disrupt planning for manufacturers.

The biggest bottleneck is not mining but refining and magnet production. Very few non-Chinese facilities can convert REE ore into high-purity oxides or metals. Refining requires technical expertise, large-scale hydrometallurgical operations and strict environmental management. This concentration highlights the strategic importance of developing alternative supply chains outside China. As a result, new supply takes years to develop.

Australia is emerging as a critical diversification hub in this sector. Lynas Rare Earths operates the only major non-Chinese separation facility and supplies about 8% to 10% of global refined output. Several Australian developers are progressing magnet-metal projects supported by international partnerships and government incentives. While building fully integrated supply chains remains challenging, Australia’s geological resources, regulatory stability, and strategic alliances make it a pivotal piece of the global REE market.

Investment Implications and Market Opportunities

Rare earths are increasingly emerging as a strategic, under‑followed commodity theme, offering potential upside for investors positioned to navigate supply-chain dynamics and geopolitical factors.

Upside for REE Miners and Processors: Non-Chinese producers with integrated mining and processing capabilities stand to benefit disproportionately from rising global demand. Lynas Rare Earths, for example, operates one of the few heavy-REE processing facilities outside China, providing valuable diversification for OEMs seeking greater security. Well-capitalised developers with credible processing plans may also attract increased strategic interest from governments and end users.

Policy and Strategic Incentives: Western governments, particularly in the US, Europe and Australia, are increasingly prioritising secure, domestically or allied-controlled supply chains for critical minerals. Heightened export controls from China, coupled with national-security considerations, create a supportive policy environment for investment in alternative REE production and processing infrastructure outside China.

Potential Catalysts: Several developments could materially tighten the supply-demand balance and influence market sentiment. These include new project approvals, expansions in processing capacity, investments in magnet manufacturing, and advances in environmentally friendly refining. Lynas’ commercial-scale production of heavy REE oxides such as dysprosium in 2025 exemplifies how operational milestones can drive both supply security and price appreciation.

Risk-Return Considerations: While structural demand growth creates upside potential, investors must consider long development timelines, technical risks, environmental constraints and volatile pricing. Substitution and recycling technologies, though improving, are unlikely to replace primary supply this decade.

Overall, REE-linked companies provide exposure to a high-impact thematic that sits at the intersection of electrification, renewable energy and advanced technology.

Conclusion: Rare Earths as a Strategic Market Theme

Rare earth elements have moved from niche industrial inputs to essential components of the global shift toward clean energy and advanced technology. As demand accelerates across EVs, wind turbines, electronics and AI hardware, the need for reliable REE supply will continue to grow. China will remain the dominant producer and stands to benefit from rising consumption, while Australia and other emerging suppliers are beginning to provide meaningful diversification.

For investors, the rare earths sector offers a dual pathway: exposure to established Chinese leaders that anchor global supply, and optionality through emerging non-Chinese producers that support a more resilient supply chain. As electrification and digital adoption expand, REEs are positioned to remain a key long-term investment theme.

Access our free Rare Earth Stocks Report for detailed analysis of ASX-listed opportunities by clicking here.

Subscribe to our newsletter

Disclaimer: This article does not constitute financial advice nor a recommendation to invest in the securities listed. The information presented is intended to be of a factual nature only. Past performance is not a reliable indicator of future performance. As always, do your own research and consider seeking financial, legal and taxation advice before investing.